When you’re swapping your stock engine and/or transmission for a different model, the right parts and accessories are a must to ensure the performance upgrade you paid for. In these situations, modders will almost always need a bellhousing adapter, and they may require a bellhousing index reducer, too. Why are these parts important and what do they do? Advance Adapters has the answers to these questions and others to help beginner DIYers.

What Is a Bellhousing Adapter?

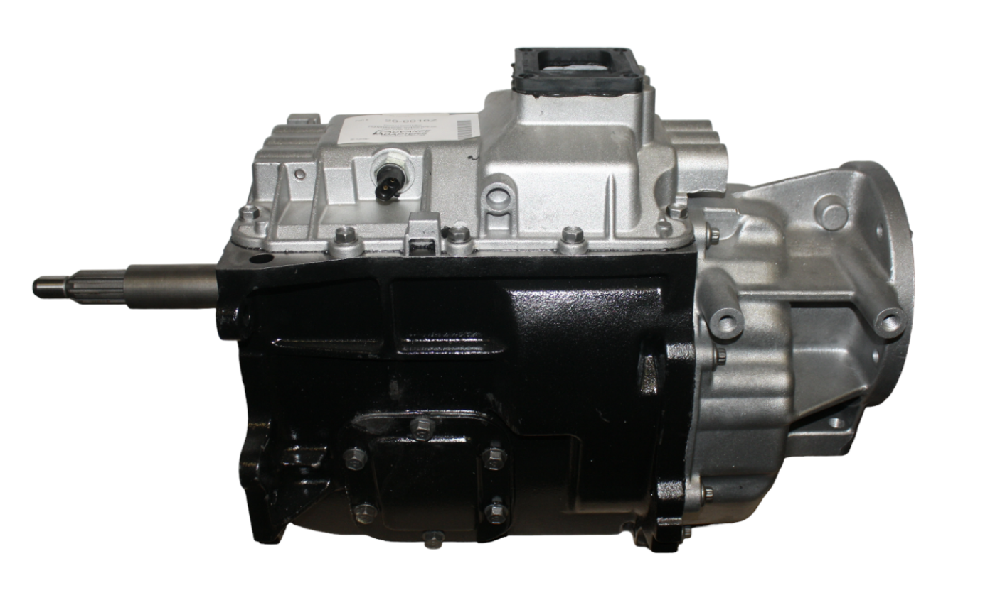

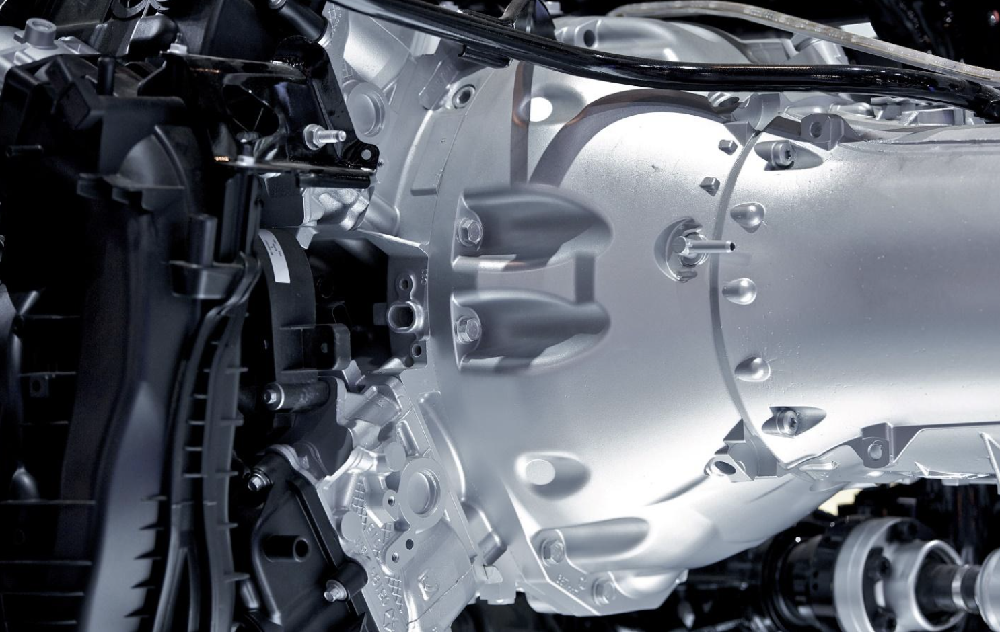

A bellhousing adapter allows you to connect engines and transmissions that weren’t originally designed for each other. In factory form, these components are made for certain connections. For example, OEM AX15 and NV3550 transmissions were mated to an AMC 258 4.2L or Jeep 4.0L engine. If you want to pair these transmissions with another engine, such as a Ford 302 or Chevy LS, the transmission input shaft or torque converter will not link properly because the engine bellhousing has a different bolt pattern.

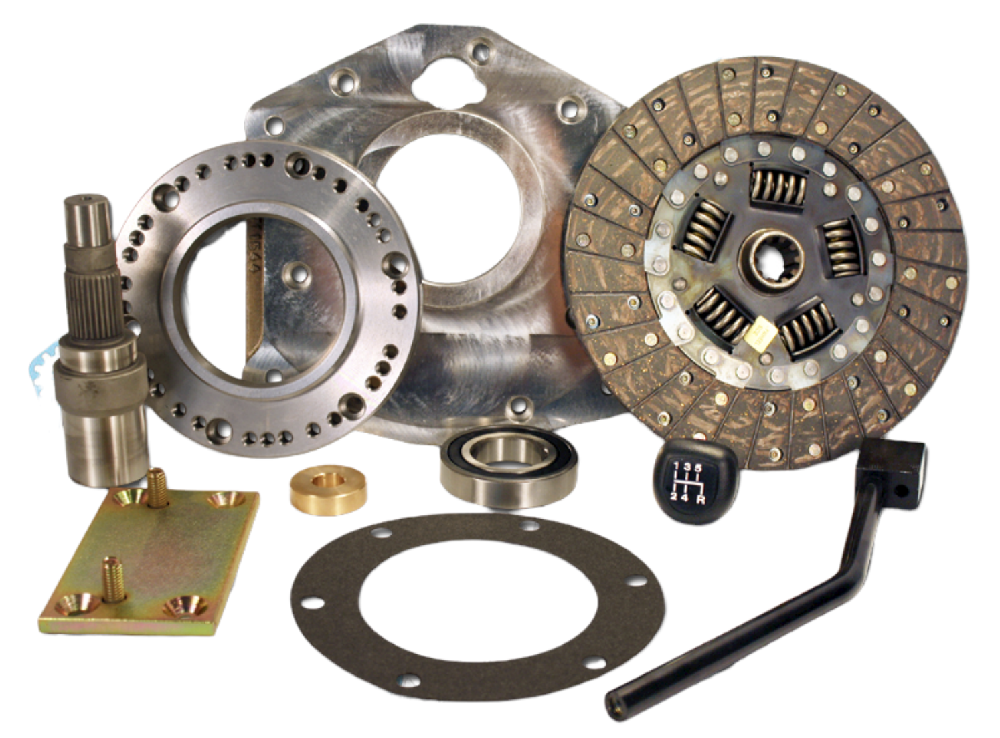

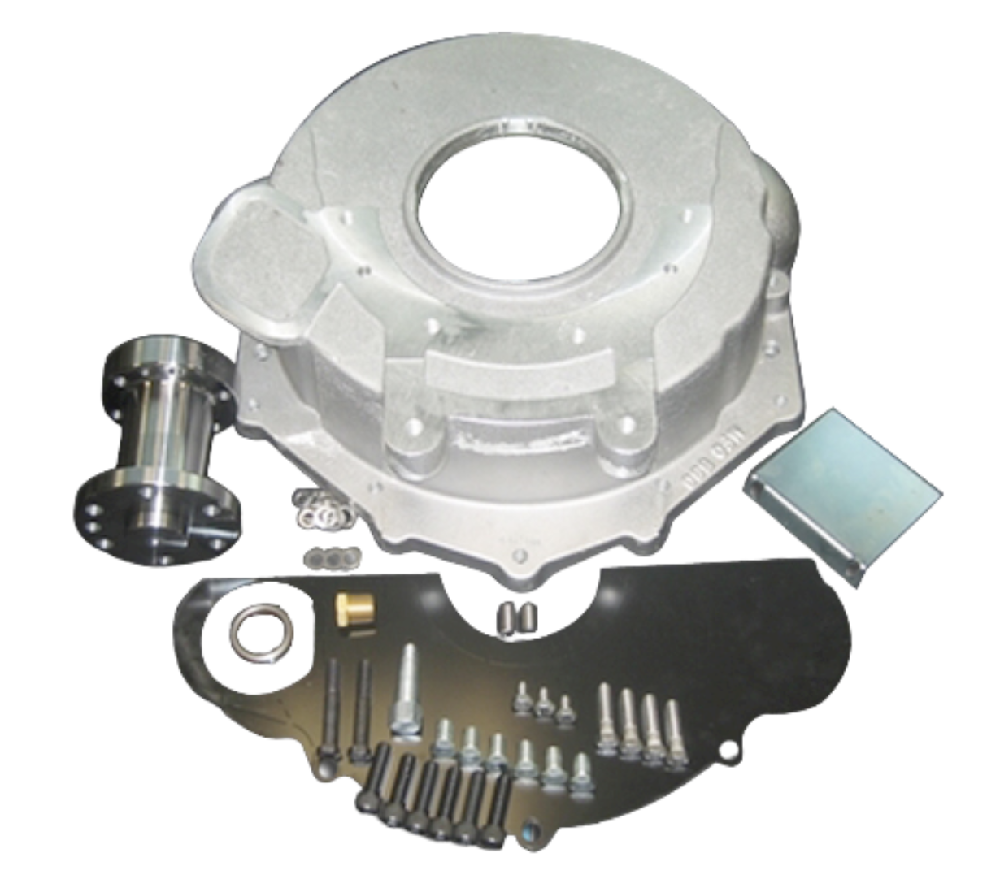

Engine-to-transmission adapters let these components fit together so you can run the combination you want with maximum power transfer, smoothness and longevity. Adapters are used to adapt a variety of components from automakers like Jeep, Ford, GM, Toyota and Honda. Kits contain various parts you need for a conversion, such as a new flywheel housing, flex and cover plates, temperature and oil pressure sender adapters and assorted installation hardware.

Note that before buying a bellhousing adapter package, you should ensure the transmission and engine power ratings are similar enough and that there is sufficient installation space for your desired combo. Just because you theoretically can mate an engine and transmission doesn’t mean you should try.

What Is a Bellhousing Index Reducer?

In certain situations, a bellhousing adapter may not be enough for your conversion; you may need an index reducer, too. The bellhousing index diameter is the size of the opening where the transmission input shaft goes, and it must be centered and aligned within 0.005 inches. Along with the bellhousing bolt pattern being different, the index diameter may be larger than tolerances allow. This is especially common when mating newer engines to older transmissions, as newer engines tend to have larger index diameters.

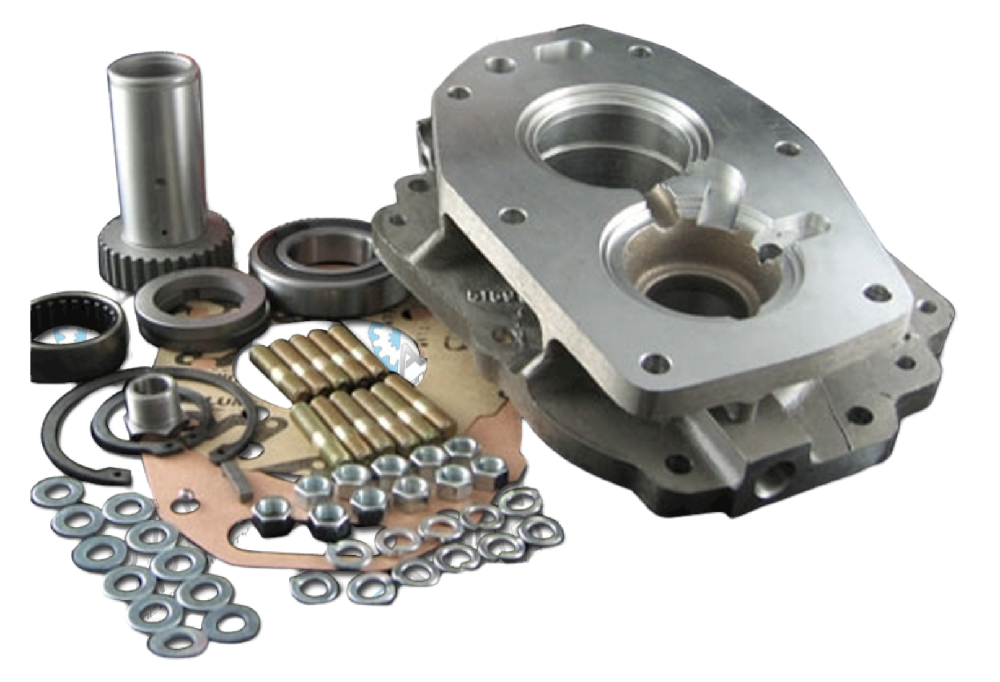

For smaller gaps, you can use offset dowel pins to make up the differences. Sometimes, though, a bellhousing index reducer is necessary. By inserting these aluminum adapter rings and retainers, you make the index diameter smaller so it’s easier to align the transmission shafts. You’ll need to measure the bellhousing index and transmission input shaft to determine what reducer you need; multiple reducers are often available for different drivetrain combos.

Connect Your New Drivetrain Components

Having the right adapters for a drivetrain conversion makes installation easier, improves performance and lowers the risk of early failure. Be sure to use high-quality bellhousing adapters and index reducers that can handle the extra power and torque you’re looking for. The experts at Advance Adapters can answer any other questions you have about drivetrain conversion adapters.