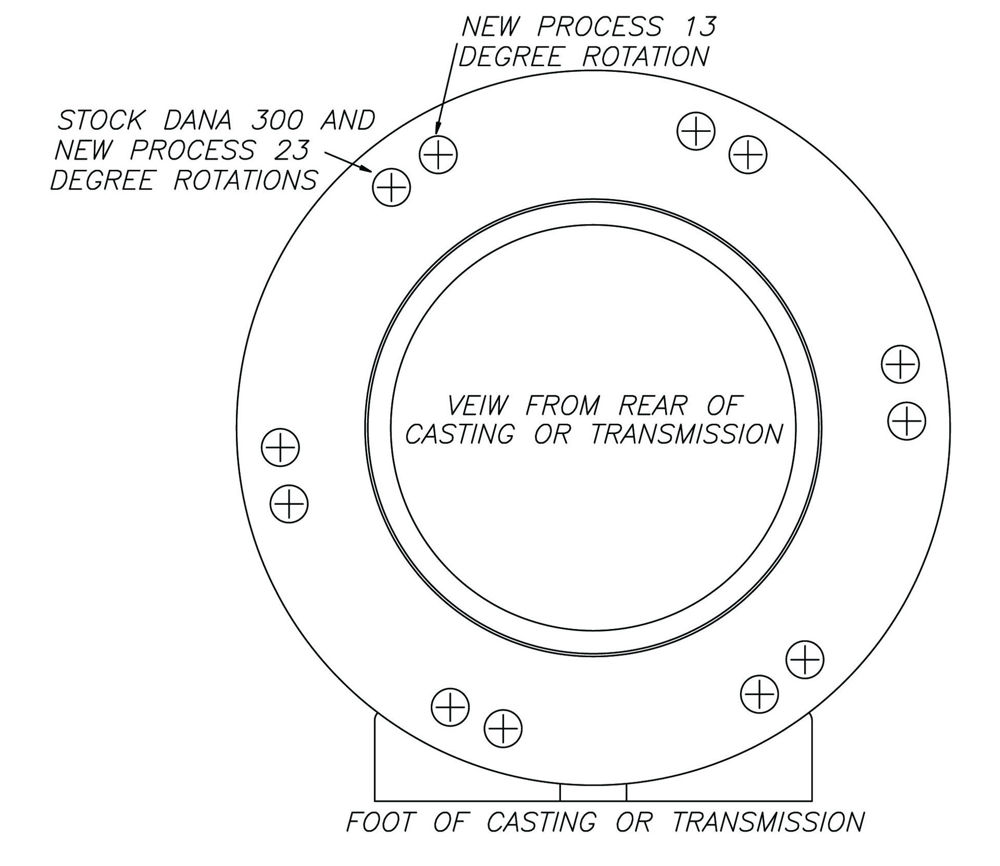

General Information: The New Process transfer cases used in late model Jeeps were always a left-hand drop configuration and had the same circular bolt pattern as the Dana 300. One of the differences between the Dana 300 and New Process transfer case is the rotation. The stock rotation on the New Process transfer case depends on the year of the vehicle and the stock transmission used. The rotations are approximately 13 or 23 degrees. Most of our adapter housings will have both sets of six adapter-to-transfer case mounting holes.

The input splines on these transfer cases vary from 21 to 23 splines, and the transmission that is mated to these transfer cases had either a long or flush output shaft length. It is crucial that you identify the correct spline length and tooth count before ordering any adapters.

There are numerous styles of New Process transfer cases and you must be very careful in making your identification of such. The first units were the NP207s, and they were used in the early model Cherokee Jeeps. The full size Jeep trucks and Grand Wagoneers used the NP208. Jeep soon added the NP231 which replaced the Model 207 in 1987. A Model NP242 was also added for the full time 4WD models. Then with the addition of the Jeep Rubicon came the NP241OR RocTrac.

SPLINES: With all of the variations in model numbers, the only variation that we see concerning transmission adaption is the size and tooth count of the transfer case input spline. The New Process transfer case has two basic spline counts and each spline count has two different lengths. Most New Process transfer cases were available with these two different input splines. The input splines of the transfer case can be changed, if necessary, but the complete transfer case will need disassembly.

The easiest way that we have found to identify the proper transfer case input is by identifying the stock transmission that Jeep used. The 21 and 23 spline output shafts vary on different transmission models. The AX15 transmission is always 23 spline and protrudes 1/2” beyond the face of the transmission. The Torqueflite and NV3550 are normally a flush 23 spline. The AX4 & AX5 always had 21 splines and were flush with the back of the transmission adapter up to 1996; and then in 1997 were the same as the Peugeot transmission which is always 21 splines and protruded 1/2” beyond the back of the transmission adapter housing. We have seen the AW4 automatic transmission in both a long 21 & 23 spline.

NP231: In 1987, Jeep began the gradual introduction of the New Process 231 transfer case. The NP231 was initially introduced into the Jeep Cherokees, followed shortly thereafter into the Wrangler. Jeep enthusiasts initially received the transfer case with mixed opinions. Many Jeepers, hoping for the grand old days of the gear driven Dana 300, were obviously a little disappointed. Skeptics aside, the medium duty NP231 proved itself reliable and capable for most applications. The transfer case is by no means perfect but coupled with aftermarket upgrades, the NP231 transfer case meets the expectations of most Jeep consumers.

Identification and Features: The chain driven NP231 was offered with a driver's side front driveshaft shaft assembly only. The rear output shaft was a centered slip yoke design. The slip yoke feature caused the transfer case to be somewhat long at 21.5”. The NP231 continued to utilize the round circular six bolt pattern as seen on the previous NP207 and Dana 300 transfer cases. The NP231 case was a die cast aluminum 2 piece design. The standard 231 weighs approximately 70 lbs.

One of the easiest ways to identify the NP231 is the metal tag located on the back of the transfer case. This red and silver tag provides some valuable information concerning the transfer case. This tag indicates from top to bottom: the model type, production build #, date, and lastly 2:72; identifying the standard low range for the NP231.

The NP231 operates as 4 basic functions: 2H, 4H, N, and 4 low. Since the transfer case is a chain driven design, a true twin stick is not functionally available.

The speedometer feature of the NP231 can be broken down by three different styles. The speedometer was always located in the rear nose cone of the NP231. The 1987-1991 models used a standard mechanical drive which basically turned a cable. In 1992, the NP231 featured a similar mechanical drive; however, the spinning gear was converted to a digital square wave signal. The interchangeable plastic gears were the same as previous mechanical units. These replaceable gears allow the consumer to recalibrate their speedometer quickly and easily when doing common tire, and ring and pinion changes. The TJ introduced a similar vehicle speed sensor (VSS); however, the speedometer drive used a new shorter gear assembly.

On some of the Jeep 21 spline transfer cases, we require the input gear to be swapped out for a 23 spline. We offer three options:

P/N 716053 - New Process T/C 23TH input (used for flush output shaft stickout on transmission)

P/N 716054 - New Process T/C 23TH input (used for long output shaft stickout on transmission)

On Jeeps 1995 & newer, New Process used a different planetary assembly. The two part numbers previously listed will not work with these transfer cases. To the best of our knowledge, this transfer case can be identified by one of three case model numbers: 5209-7894, 5209-8361 & 5209-8540. If you have one of these model transfer cases and wish to change to a 23 spline input, the input gear required is P/N 716095.

The gears listed above will not work with the NP207 transfer case. If you have a 1987 Jeep equipped with the NP207 21 spline input gear and wish to add some strength to your drivetrain, you can purchase a new 23 spline input gear (P/N 716096). This new input gear was designed for transmissions with a flush output shaft stickout. Transmissions having a .500” stickout past the adapter housing will require the input gear length to be modified. On certain applications the transmission output will have to be trimmed.

The Jeep NP231 was used for years and is one of most commonly used transfer cases today. Yet, one of the biggest faults of this transfer case is the overall length. At 20+ inches, this creates an extremely short rear driveshaft in the Jeep YJ & TJ Wranglers; and when the vehicle is lifted or a transmission swap is performed it becomes even more crucial. In addition to a lift kit installation, larger tires are usually the next upgrade. Strength and driveline angle of the output shaft then becomes a concern.

To make the NP231 better suited for these upgrades, we have designed our “Fixed Yoke” kit with the best features available. We manufacture a new one-piece tailhousing that will add 3-1/2” to 4” to your rear driveline length on a YJ, and up to 6” on a TJ. This will allow you to obtain a better driveshaft angle and eliminate driveline vibrations. We also manufacture a new 32 spline output shaft that is over 50% stronger than stock. This kit, along with a new 1310 series C.V. yoke, makes the NP231 a better transfer case for trail use. A full set of installation instructions is provided to assist in the installation of this kit. 50-7906

If you’re looking for a non C.V. yoke or a flanged yoke option, kit P/N 50-7907 allows for these options. This kit can be ordered with a 1310 or 1350 non-C.V. yoke or a flange yoke can be added.

NP231 rebuild kits: We offer two kits for rebuilding the Jeep NP231, 29-2322 is a master rebuild kit for the 1995-06 transfer cases, and 29-2323 is a small parts kit for the 1995-06 NP231's.

NP207, NP208, NP242: These transfer cases will work the same with our transfer case adapters. We do not offer any upgrades to these units.

NP241OR ROCTRAC: In 2003, Jeep introduced the rugged Rubicon edition Wrangler. The Rubicon received numerous upgrades in comparison with a standard Jeep Wrangler. One of these upgrades was the venerable NP241OR RocTrac Transfer Case. The RocTrac transfer case offers the strength of a full size truck transfer case while also offering an impressive 4:1 low range.

The design of the NV241OR RocTrac is based off of the robust NP241 transfer case commonly found in full size Dodge/GM trucks. Much like the truck NP241, the RocTrac received an impressively large 4 planetary gear system and a wider chain. The RocTrac has a noticeably large front section where it houses this larger 4:1 planetary gear system. The RocTrac has numerous ribbing reinforcements around the case exterior for added case strength. The RocTrac comes factory with a 32 splined rear output shaft equipped with a fixed yoke. The front driveshaft is located on the driver's side of the vehicle and is likewise offered with a 32 spline output.

As with most chain driven transfer cases, the RocTrac operates in four shift modes. The transfer case shifts in the following patterns: 2WD high, 4WD high, Neutral, and 4WD low. The case can be identified by the silver and red metal identification tag that is riveted to the rear section of the transfer case. The RocTrac measures 15-1/4” in overall length and weighs in at about 92 lbs. The front of the transfer case uses the standard Jeep round circular 6 bolt pattern as found on the NP231.

Although the full size NP241 looks similar to the RocTrac, the internal components are different. Most internal parts, including both the 4:1 planetary gears and input shafts, are not interchangable between the RocTrac and a standard NP241. We offer numerous transmission-to-transfer case adapters for the 23 spline version of the NP241OR.

The TJ Rubicon version of the RocTrac utilizes a tone wheel for the speedometer. The speedometer also commonly referred to as the “vehicle speed sensor” or “VSS” is located on the rear nose cone near the rear yoke. It operates off of a three-wire, square wave signal. It should be noted that changes in tire size or ring and pinion typically require a Jeep dealership to re-flash the computer for accurate speedometer calibration. As an alternative to “re-flashing”, numerous companies offer vehicle speed calibration controller boxes.

All Jeeps 1987-06:

DRIVESHAFT CLEARANCE: When converting to a new transmission, driveshaft modifications are normally necessary. Jeeps with the NP231 now have the advantage of gaining needed length for suspension travel. We offer a new short shaft “Fixed Yoke” kit that will add 4” of rear driveshaft length on a YJ, and up to 6” on a TJ. Regarding front driveshaft clearance, this is not usually a problem. Care should be given on some manual transmissions with reference to the clutch release arm and slave cylinder mounting.

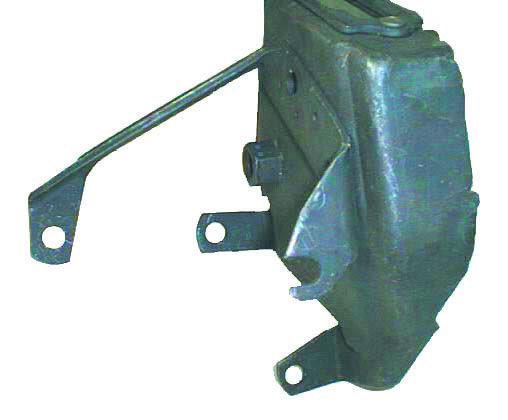

TRANSMISSION/TRANSFER CASE SUPPORT PLATE: All of the adapters we manufacture offer a support pad machined on the casting. In most cases, this pad will not line up with your original skid plate mounting slots. If you are planning to reuse your stock rubber support or one of our new supports, we suggest that you retain your skid plate in the stock location and add two new holes to your skid plate to fasten the rubber support. The supports below can be used to fasten our adapter to your stock skid plate.

P/N 716008 - New rubber support (Jeeps 1987 & Up)

P/N 716055 - Transmission support (limited applications)

Some vehicle applications may require a spacer between the adapter crossmember foot and the rubber mount. This is to provide ample clearance between the transmission and the skid pan. We offer a 2” spacer that works well. Since all applications differ, it’s hard to determine or recommend when this additional mount is needed. P/N 716048

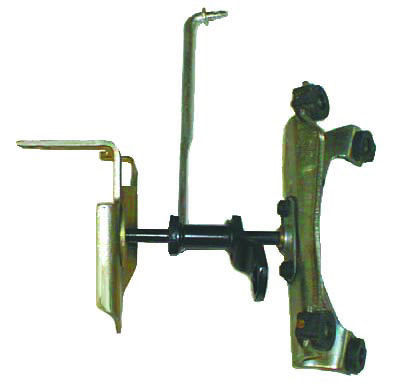

TRANSFER CASE SHIFTERS: There are several configurations used on the New Process transfer cases. We manufacture several brackets to assist you in retaining your stock shifter; however, some applications are not available. You may be required to fabricate your own brackets to work with our adapters. The photos below will help you identify the stock linkage your vehicle may have. This will assist you as to whether or not we offer additional brackets to mount your linkage. Brackets left to right are (1)AX15, (2)Jeep TJ, (3)Universal, (4)AX5.

715523- fits 50-6300,6800 9100 transfer case adapters/ bracket 1 & 4

715542- Jeep TJ with a 13 degree rotation/ bracket 2

715545- AX15 & NV3550 to NP transfer case

All TJ models have the transfer case shifter linkage mounted to the body. This set-up uses a bell crank that pivots between a transfer case mounting bracket and a body mount. When the transfer case moves during a vehicle lift, transmission swap, body lift or use of flat skid plate, the transfer also moves. Even the slightest movement can upset geometery of the transfer case shifter mounting bracket. This misalignment can cause severe binding of the transfer case shifter. We offer an isolation bracket that, once installed, removes the mounting point on the body and isolates it to the transfer case. This isolation TJ shifter bracket is sold under 715542.

A second option is to upgrade the Jeep linkage by removing the bellcrank completely. We offer a complete cable shifter for TJ NP231 or RocTrac transfer case. P/N 715543.

Additional shifter parts:

715545C - Adjustable connector rod with rod ends between the transfer case shifter lever and gated shifter.

715545H - Replacement transfer case handle & black anodized aluminum shift knob.

Atlas: The most popular option is the Advance Adapters Atlas. Our heavy duty gear-driven transfer cases are the ultimate in gearing and strength. These units are the solution for combining both on and offroad performance. When you want or need peace of mind on the trail, in the rocks, on the sand, or in the mud, the Atlas is the transfer case for you.

The Atlas 2 Speed is 2-1/2” shorter than a NP231 with a fixed yoke conversion kit. Applications with a NP231 will have to lengthen the rear driveshaft and shorten the front driveshaft. (2SP) Atlas, 13.8” & Atlas (with AST32 short tailhousing), 11.8”

The Atlas 4 Speed is 1-3/4” to 3-3/4” shorter than a standard NP231 transfer case (length depends on which tailhousing is used). Applications replacing a NP231 will have to lengthen the rear driveshaft and shorten the front driveshaft. . The Atlas 4 speed offers you the ultimate multiple-use vehicle, The several low gearing options allow you to gear your rig for the daily driver as well as the extreme rock crawler. (4SP) Atlas, 18.75” & Atlas (with AST32 short tailhousing), 16.75”

Atlas 2SP Atlas 4SP YJ Atlas Install TJ Atlas Install

One other option for the TJ’s with the NP231 or RocTrac and the 42RLE automatic transmission is the addition of a Rubi-Crawler. This is a reduction box that provides you with a 2.72:1 low ratio in 2WD and 4WD in addition to an ultra-low range of 7.34:1 or 10.88:1. The Rubi-Crawler can be installed into a Jeep within a day without any driveshaft modifications.