Transmission Tailhousing Adapters: On these model, Jeeps (if retaining your stock transmission), Chrysler used an oil weep hole on the stock adapter housing. This weep hole was in one of two locations: on the adapter surface where the transfer case mates to the adapter, or on the bottom center of the casting near the crossmember foot. These weep holes were designed for informing you when the seal in the tailhousing would fail. The Atlas does not always have the same input shaft length as your stock New Process transfer case to make contact to this seal and the Atlas has a double lipped seal in the front of the transfer case to prevent any fluid transfer. Therefore; we highly recommend plugging the weep hole using RTV Blue silicone (if on the adapter housing face), or RTV Blue silicone and a sheet metal screw (when located near the crossmember foot). This will prevent any type of fluid leak when installing the new transfer case. Note: the NV3550 transmission does not have this weep hole on the transmission.

Speedometer: These vehicles utilized the same type of speedometer housing in the stock New Process transfer case. The Atlas was designed to accept the stock New Process speedometer housing. If your speedometer is correct (regarding tire size and axle gear ratio) the stock speedometer will not change. If you plan on changing tires or gear ratio, please use the Speedometer Charts located in our application guide. The speedometer housing is retained into the Atlas with a metal clip. When the housing is installed into the Atlas tailhousing, the speedometer housing should be rotated clockwise or counterclockwise until the speedo gear meshes with the Atlas output speedometer gear. The new seal kit you received with your Atlas should be installed to prevent any fluid leakage.

Transfer cases like the Rock Trac 241 use a sensor rather than a speedometer housing. The speedometer housing found on the NP231 will generate the same signal as the Rock Trac sensor. If you are replacing a Jeep transfer case that used a sensor and not a speedometer housing, then we can assist you with the correct parts to fit the Atlas transfer case and retain your stock speedometer. Our 300640.

Rotation & Oil: The two stock rotations of the New Process transfer case are 13 or 23 degrees. We recommend the Atlas be installed at either a stock or higher rotation. The recommended 2 quarts (2-speed Atlas) or 3 quarts (4-speed Atlas) of oil will be used. As mentioned in the application guide, if the Atlas is overfilled it will purge the excess oil out the breather tube. You should also replace the stock The TJ Wrangler began to be manufactured in 1997. This vehicle model is normally equipped with either an automatic transmission (Torqueflite & 42RLE), or a manual transmission (AX5, AX15 & NV3550). The installation photos in this section relate to both automatic & manual transmission applications.

Shift Indicator Switch: The Atlas is designed to accept the stock TJ 4WD indicator switch on units produced before August 2014. We Changed the thread size and location on our shifter controls requiring the TJ's to use a new Pollak switch part number 300364 to plug into the stock harness. The switch only indicates the dashboard 4WD light. Unlike the previous YJ model, TJs have a full time engaged front axle. This switch is installed into the Atlas shifter housing without the use of any spacer or washer. Note: Since the front axle is always turning, the TJ uses a C.V. front yoke.

Shifter Installation: The twin stick for the Atlas 2 speed TJ application has three designs for a hard linkage. 303003L should be used with a AX5, AX15 & NV3550 transmissions.

303002L should be used with the Torqueflite automatic transmission. These shifters are designed specifically for these applications and fit the stock console.

303002U should be used with the 42RE and the NSG-370 transmissions or any vehicle that has had a drivetrain swap. This shifter has a long extension from the front of the Atlas and can be modified to fit most applications.

303020 works on all TJ's. The cable shifters bolt directly to the floorboard and enter the vehicle through the stock console.

The Atlas 4 speed shifter options fit the same as the 2 speed shifters, however; there are a few different components so we also have different part numbers.

344003 should be used with a AX5, AX15, NSG-370 & NV3550 transmissions.

344002 should be used with the Torqueflite & 42RLE automatic transmission. 344002 should also be used with any vehicle that has had a drivetrain swap. This shifter has a long extension from the front of the Atlas and can be modified to fit most applications.

303020 works on all TJ's. The cable shifters bolt directly to the floorboard and enter the vehicle through the stock console. Note the NSG370 transmission should also use a 1/2" spacer when bolting to the Atlas 4 speed.

Shifter linkage upgrades: The connection rods for the Atlas were designed to be universal so they could be adjusted for the various drivetrain lengths. The stock linkage works well for the majority of applications and vehicles. The extreme racers and rock crawlers on the other hand were looking for a linkage that would withstand the abuse that they are putting their rigs through. The two kits offered are upgrades that work with the standard handles and use heim joints that are bolted to the Atlas linkage. Anyone can upgrade to this kit as it will work on all Atlas ridged mounted twin stick applications. 303040 or 303041.

Installation Notes:

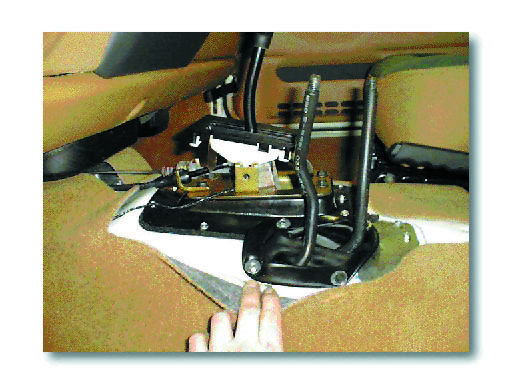

The stock floor mount (shifter and linkage) is removed before initial installation. The console and driver's seat should also be removed for ease of installation. The sticks will come up through the stock floorboard hole. You will be required to cover a small portion of the stock hole. The rear driver's side will need a piece of sheet metal to be added. Make sure the handles move freely and don't touch the floorboard. Interference will cause the unit to pop out of gear.Place the stock console in its original position to test fit the Atlas handles. Rotate the twin stick assembly so that it aligns with the console slot. Once the correct position is obtained, remove the console again.

Shift the Atlas into 4WD low (both handles forward), verifying at least a 1/2" clearance between the handle and the body. Test fit the shifter boot and boot ring. You will need to add a small piece of sheet metal at the REAR of the boot to extend the floorboard. Check the shifter boot and the handles for any interference or binding. Fasten the shifter boot and boot ring to the floorboard using high temperature silicone for an airtight seal around the boot area. Note: Sometimes the shifter boot will tend to bunch up, causing the unit to pop out of gear. We have found that if you apply a small amount of grease where the boot and handles contact, it will help to prevent this problem.

Atlas 4 speed with the reduction shifter installed next to the emergency brake.

The TJ Wrangler began to be manufactured in 1997. This vehicle model is normally equipped with either an automatic transmission (Torqueflite & 42RE), or a manual transmission (AX5, AX15 & NV3550). The installation photos in this section relate to both automatic & manual transmission applications.

Crossmember & Body Modifications

The Atlas can be installed without spacing the stock crossmember, even with a suspension lift. Without spacers, it is crucial that the pinion angles be considered. Improper pinion angles can cause driveline noise which could easily be misinterpreted as transfer case noise. If you opt to use some type of spacers on your crossmember, this can affect the installation and operation of your twin stick shifter. NOTE: The Crossmember modifications do not need to be made when you are upgrading to a 4 speed Atlas.

If you plan on using a lift kit in addition to your new Atlas, it is important that you correct your pinion angle when running a rear C.V. type driveshaft. The pinion angle should be equal to that of the output driveshaft. Many aftermarket suspension systems allow you to adjust the lower control arm length to give you the pinion angle you need.

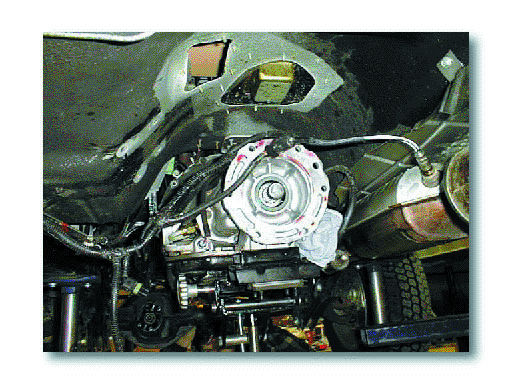

Note the new Atlas installed with no crossmember spacers (which robs you of precious ground clearance), and the gain of over 6 inches of new and much needed REAR driveshaft length.

On TJ installations, you will have a few modification options when installing the Atlas transfer case. The first and most desirable option is to rotate the Atlas to a shallower than stock rotation. This will cause interference with the floorboard of the vehicle on the driver's side. By positioning the Atlas in the vehicle and rotating it up to where it contacts the body, you will need to mark this location.

Modifications will require some 'hammering' on the floorboard to provide clearance. By installing the Atlas with this modification, you will obtain the necessary crossmember clearance. If your vehicle has a body lift, modifications to the body may not be necessary.

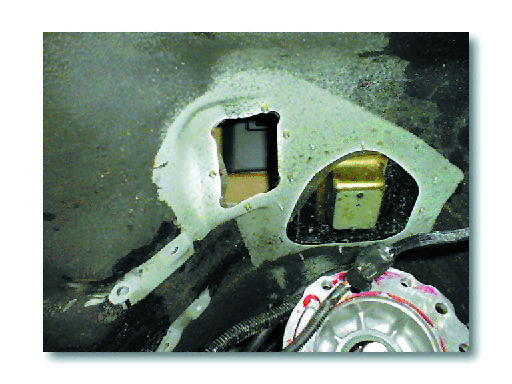

A second option is to use the same rotation as your stock transfer case. Since the Atlas is physically larger in size than the stock New Process case, modifications to the skid pan will be required. The Jeep TJs used a few different skid plate designs, so the modifications may vary. We have shown some of the most typical modifications required. There are also several aftermarket companies that offer new skid plates that fit closer to the frame rails and have been built for the Atlas transfer case.

No matter which option you decide to do, we recommend that you provide clearance on the crossmember for the Atlas drain plug. This drain plug is located on the access pan of the transfer case. On stock AX15 & NV3550 manual transmission applications, the crossmember bracket will need to be modified.

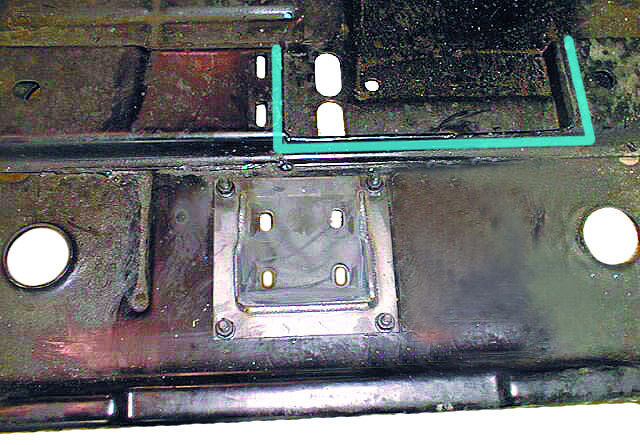

The stock manual transmission bracket before modifications.

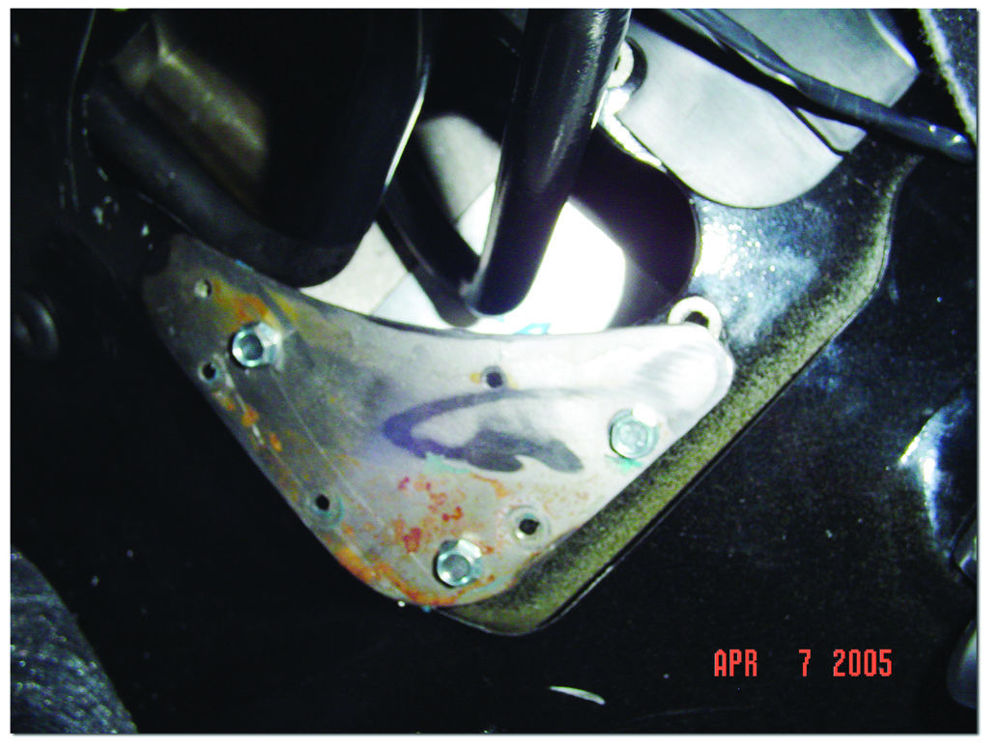

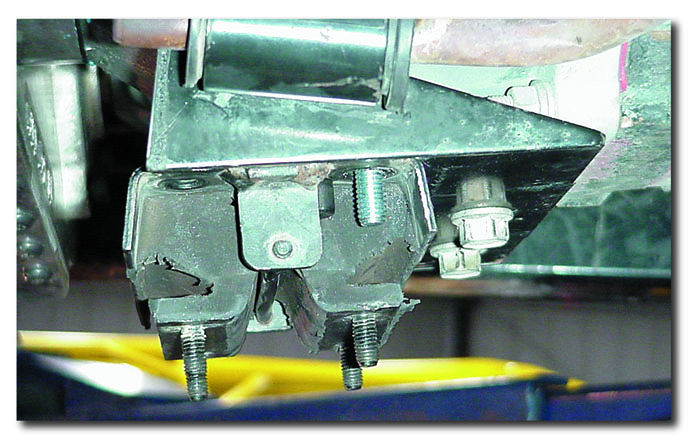

The modified transmission bracket with the rubber support in the new location.

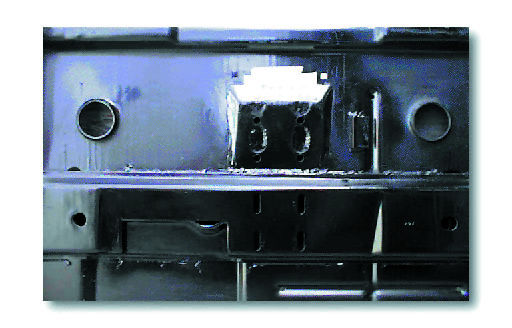

Once the bracket has been modified, the crossmember must be modified to fit the angle of the transmission and rubber support. Modified pan. The crossmember with the new rubber mounting area modified.

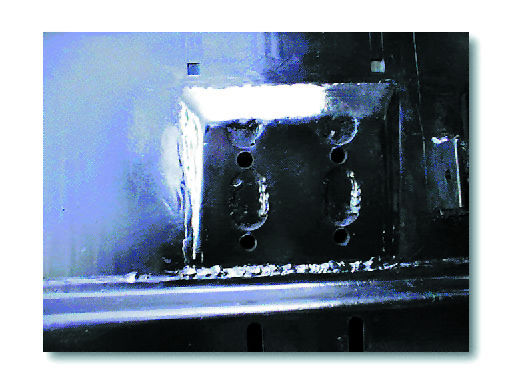

The AX5 transmission is slightly shorter than the other manual 5 speeds found in the TJs. The 1997 & newer AX5 found in TJs has a 21-spline output shaft that protrudes .500" from the back of the 5 speed. This 1/2" stick out allows for this transmission to be equipped with a 1" spacer. The 1" spacer is recommended because it allows for a cleaner shifter installation. The rubber support must be modified and moved under the transmission tailhousing. In its original

1" spacer allows for easier shifter installation Modified rubber mount. AX5 should have 1/2" output shaft stick out.